Designing a tire is quite a balancing act. The tire needs to be safe, long-lasting and as fuel-efficient as possible, but it also needs to be relatively quiet to avoid excessive road noise.

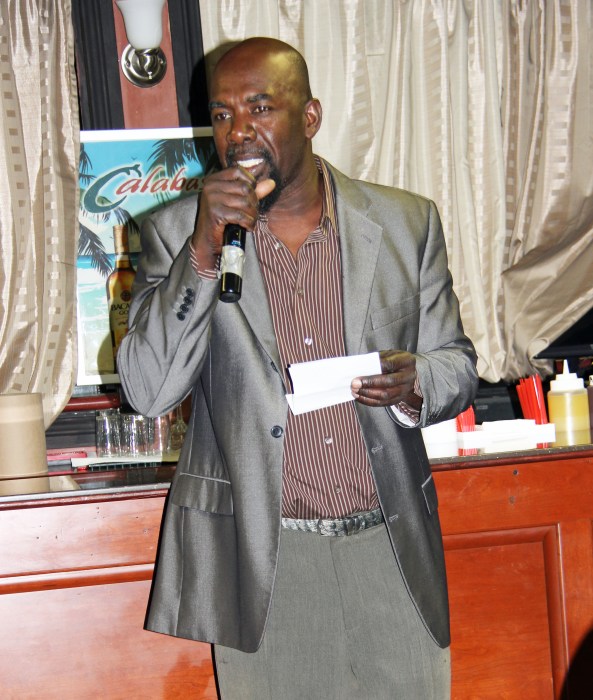

Pirelli has a research and development department that deals specifically with tire noise, especially since it is headquartered in Europe where tires have to meet maximum mandated noise levels, says Mastracchio Orazio, quality product manager for Canada for Pirelli Tire.

“There are a few factors with noise, and the most predominant one is the tread design,” Orazio says. “For example, a winter truck design will generate more noise than a summer performance tire. The (rubber) compound has a minimal effect. It depends on the tread design.”

Tire treads are made up of blocks that contain grooves and sipes, the tiny slits in the tread face that help increase traction.

“You see more and more tires that have a modern tread design,” Orazio says. “Most of them are asymmetrical or directional. You need to make sure that the pitch of the tread blocks is not the same on the left side as on the right side, because when the wind hits the tread blocks, it generates a certain level of decibels. If you space out the tread blocks, it breaks the wind noise.”

Tires are tested for noise in a special “quiet” room, with microphones inside and outside the car. The vehicle is run on rollers in the floor, with the microphones picking up and analyzing the sound. The engineers work to make the tire as quiet as possible, while still working in conjunction with those who are designing the tread and assessing the tire’s longevity.

If they go too far in one direction, they sacrifice at the other.

“We have to consider the safety,” Orazio says. “Noise is up there, but safety is the priority.”