By Min Zhang and Enrico Dela Cruz

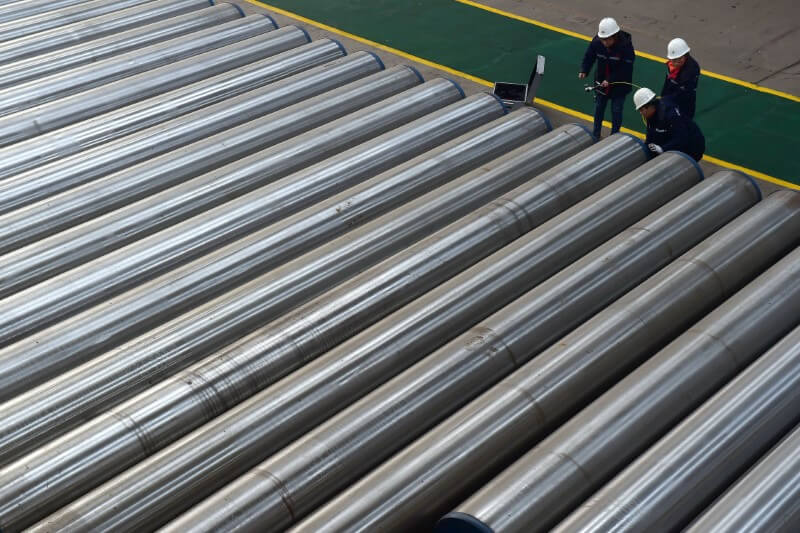

BEIJING/MANILA (Reuters) – China’s appetite for high-grade iron ore this winter looks set to drop from the peaks hit in recent years as steel mills try to cut costs and prop up profit margins weighed down by the nation’s slowing economy, industry sources said.

Demand for high-grade iron ore, which produces more molten iron than the same amount of lower grades of the steelmaking raw material, typically climbs from November to March, when China’s winter anti-smog campaign forces smokestack industries to curtail output and use cleaner inputs to help clear the air.

But authorities in the world’s top steel producer are taking a more lenient stance on emissions while the Chinese economy sputters, allowing mills room to cut costs by using more lower, cheaper grades of ore and fewer high-grade supplies.

(GRAPHIC: China’s iron ore prices – https://fingfx.thomsonreuters.com/gfx/mkt/13/655/655/price%20spread.png)

This trend impacts ore exporters like Rio Tinto, BHP and Vale and is captured by the narrowing price spread of grades having between 65% and 62% iron content. So far in 2020 that price difference has been 20% narrower than it averaged in January 2019.

Miners in top global ore producer Australia are expected to benefit most from this switch as they mostly produce medium and low-grade ores, said Erik Hedborg, senior iron ore analyst at CRU consultancy.

Brazil’s Vale SA, dominates the high-grade market, along with small miners in Canada, Ukraine and Sweden.

MARGIN SQUEEZE

China’s trade war with the United States slowed its economy and sapped metal demand, prompting the penny-pinching by the Chinese steel mills.

A 60% surge in ore prices in early 2019 after a dam collapse at one of Vale’s mines in Brazil also hurt steelmakers, pushing production margins well below where they averaged in 2018, when robust construction and manufacturing fueled a steelmaker boom.

Rebar margins in China’s main steel hub in the north averaged 241 yuan per ton during the second half of 2019, roughly 70% below 2018’s average of 788 yuan per ton, according to brokerage Jinrui Futures.

(GRAPHIC: Profit margins for rebar and HRC at Chinese mills – https://fingfx.thomsonreuters.com/gfx/mkt/13/557/557/profits.png)

Sources say that even if China and the United States reach a trade deal, steel margins are not likely to rebound to their former peaks any time soon.

“Profitability in the steel industry may bounce back slightly from today’s low level, but it’s certainly not returning to the elevated 2018 levels,” CRU’s Hedborg said.

UNCLEAR OUTLOOK

While Beijing rolled out measures to prop up the economy in 2019, it’s unclear how much additional stimulus may emerge in 2020 to boost steel demand, said Wu Shiping, an analyst with Tianfeng Futures.

China’s steel use is seen dropping 0.6% this year, and iron ore demand by 3.1%, dragged down by slowing real estate and car sales, according to government consultancy China Metallurgical Industry Planning and Research Institute.

(GRAPHIC: China’s monthly iron ore imports – https://fingfx.thomsonreuters.com/gfx/mkt/13/953/950/Annotation%202020-0…)

“Overall iron ore demand in the first quarter should be relatively stable,” said an executive at a big steel mill in central China.

“But as profits are sliding, and downstream demand remains uncertain in spring, mills are relatively cautious on restocking,” he said, requesting anonymity as he is not allowed to speak to media.

(GRAPHIC: China’s crude steel output and utilisation rates at mills – https://fingfx.thomsonreuters.com/gfx/mkt/13/836/834/Annotation%202020-0…)

(Reporting by Min Zhang in Beijing and Enrico dela Cruz in Manila; Editing by Shivani Singh, Gavin Maguire and Tom Hogue)