CHICAGO (Reuters) – Dan Digre, head of MISCO Speakers, was on edge before the coronavirus outbreak hit the global economy. Payment of hundreds of thousands of dollars in Chinese tariffs had wiped out the profit and dwindled the cash balance of the Minnesota-based loudspeaker maker.

Now Digre is grappling with dropping sales and payment delays. With cash ever harder to come by, he must cough up the money for President Donald Trump’s 25% tariffs on parts that Digre imports from China for speakers used in everything from mass transit systems and gaming devices to essential ventilators and military equipment.

He is not alone. As a deepening economic recession dries up their revenue streams, hundreds of import-dependent large and small businesses are finding it tougher to survive the pandemic due to tariff costs.

“You are caught in a double bind,” Digre said. “You need cash to operate your business. At the same time, you are not getting cash in.”

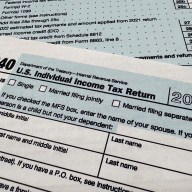

Despite a “Phase 1” deal, $370 billion of Chinese goods imported into the United States are still subjected to tariffs of up to 25%. Similarly, 25% tariffs on foreign steel and a 10% duty on aluminum imports remain in place – taxes on American businesses at a time of little revenue.

“Companies are paying taxes on goods that they can’t sell right now for the stay-at-home orders,” said Jonathan Gold, spokesman for Americans for Free Trade – a broad coalition of U.S. industry groups that lobby against the tariffs.

Since March 2018, Trump has been employing tariffs as part of a restrictive trade policy to rewrite terms that he says have destroyed American industry and jobs.

Keeping tariffs in place on Chinese goods he says would maintain leverage over China for a Phase 2 trade deal. Further relaxing the metal tariffs could jeopardize domestic producers, according to some U.S. steelmakers.

San Diego-based athleisure maker Vivacity Sportswear has been paying a 25% tariff on one-third of its raw materials that are sourced from China, leading to a 15% drop in profit last year, CEO Vivian Sayward said.

In the past two months, the company’s revenue has dropped 80% and inventory has increased by 60%. Shrinking profit margins and depressed demand have compelled it to temporarily halt all manufacturing.

Lower demand has also prompted MISCO to stop all new shipments from China. That will reduce its tariff expenses – but the company has to find money to pay for the goods that are about to arrive or have reached the United States.

NO BLANKET RELIEF

In a letter to the White House last month, executives of more than 350 American companies, including farm equipment maker CNH Industrial <CNHI.MI>, retailers Macy’s Inc <M.N>, Gap Inc <GPS.N> and J.C. Penney Co Inc <JCP.N>, urged Trump to delay the collection of duties by 90 to 180 days to help them preserve cash flow during the pandemic.

The calls for blanket relief have failed to gain traction.

In March, the Office of the United States Trade Representative took some Chinese medical products off the tariff list. It has also asked companies to file requests for duty exemptions for supplies that can be effective in dealing with the coronavirus.

Earlier this month, the Trump administration allowed importers that have faced a “significant” financial hardship due to the virus to delay payment of tariffs for 90 days for goods imported in March and April. The relief, however, will not be available to importers of Chinese goods and steel and aluminum.

USTR did not respond to a request for comment.

Meanwhile, Gap has warned it may not survive the next 12 months intact, and J.C. Penney has skipped an interest payment amid bankruptcy fears.

J.C. Penney declined to comment for this story. CNH Industrial, Gap and Macy’s did not respond to requests for comment.

“This (the pandemic) is an existential threat not (seen) since the Great Depression,” said Kip Eideberg, senior vice president of government and industry relations at the Association of Equipment Manufacturers (AEM), which represents over 1,000 companies including Caterpillar Inc <CAT.N> and Deere & Co <DE.N>.

Since March 2018, U.S. importers have been billed about $59 billion in Chinese and metal tariffs, according to U.S. Customs and Border Protection. Data compiled by consultancy Trade Partnership Worldwide, for trade group Tariffs Hurt the Heartland, shows suspending the tariffs or delaying their payments would free up as much as $3 billion of cash per month for U.S. companies.

SOARING CASH NEEDS

MISCO’s president, Digre, has requested tariff exemption for the parts that are used in the audio devices for ventilators but has yet to hear back from the government. MISCO is one of the few companies that has retained U.S. production long after other rivals moved production to Asia, primarily to China.

However, the 25% tariffs on MISCO’s Chinese components have left the company at a disadvantage against speakers that are entirely built in China and can be imported with a 7.5% duty.

The anomaly has made it harder to fully pass along the increased tariff cost to customers. MISCO spent $300,000 last year on the tariffs, but was forced to absorb most of the increased cost.

Since the virus’ outbreak in the United States in early March, many of MISCO’s customers such as Las Vegas-based gaming companies and aircraft makers have asked to stop all deliveries until further notice. Some customers are asking for longer payment terms, resulting in payment delays between 30 and 90 days. As a result, Digre says MISCO’s cash requirement has tripled.

So far, Digre has tried to avoid layoffs. Instead, the 40-hour work week has been shortened to 32 hours, and capital spending as well as advertising have been slashed.

A government-sponsored payroll protection loan has also helped. But if the business does not rebound and there is no tariff relief, Digre says it will be “very difficult” to operate beyond June.

Sayward is similarly unsure of Vivacity’s future after its cash runs out in June and the ability to obtain a government-sponsored small business loan remains difficult.

“If things don’t change and we don’t get the money, we are looking at closing,” Sayward said.

(Reporting by Rajesh Kumar Singh in Chicago; Editing by Caroline Stauffer and Matthew Lewis)